After taking a week off, Broken City Lab Office Hours started up again with a focus on getting a number of the shells for the magnetic planters completed. It was a really productive meeting with some more welcomed new faces and a whole bunch of planters now ready for the next step. It wasn’t all fun though, we lost an invaluable BCL member—Mike’s blender.

After some quick updates on what happened in the week off, Danielle and Michelle got right to the paper making process.

We bought some of these cheap scrub pads earlier in the week. Because the amount of pulp that we need is so small for the planters, these are fine and allow us to work with almost any size container to get the pulp out of.

The basic process that we’ve been using is to make a batch of pulp, pour it over these scrub pads into a larger plastic container and then press out the water from the pulp on the pad.

Danielle and Michelle led the paper making process.

Everyone around the table ripping paper, working with pulp, and making planters!

We had a generous pile of ripped up newspaper.

Here’s the planter that we field tested earlier this week.

Samantha and Nicole came out for the first time to help us.

Danielle, Josh, and Michelle work with the pulp and try to perfect the recipe.

Samantha put together a frame for the planters from Lego. We were trying to use anything that was roughly the shape and size of the original planter we made, which seemed to be a good balance of soil and weight for the magnet to hold up.

It was only a few batches of paper pulp in when the original blender we got from Mike died.

So, we headed off to Canadian Tire to buy a new blender.

There were many nice shiny blenders, but only one caught our eye, the one that was 40% off.

Of course though, there were no sale blenders in stock, though Josh tried to hack the system to find out if there were any blenders hiding in the back.

Though we tried to buy the display model, the housewares manager at Canadian Tire refused, so we went to Zellers and picked up another blender for the same price, though it wasn’t on sale.

Back around the table, Nicole patched a couple of planters with some glue and paper.

Ryan looked over the progress on the planters.

Planter processing action!

Ryan getting his hands dirty.

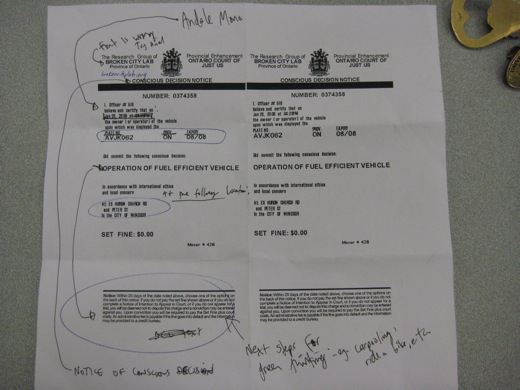

Here’s a quick shot of a project Josh has been working on, which seems fairly well-timed. We want to make some mock-up parking tickets that thank drivers of fuel efficient vehicles. This is just the first of probably a series of these.

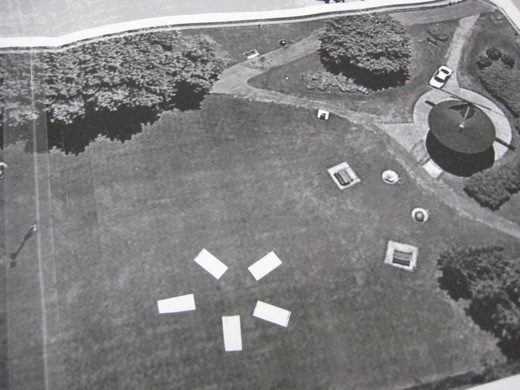

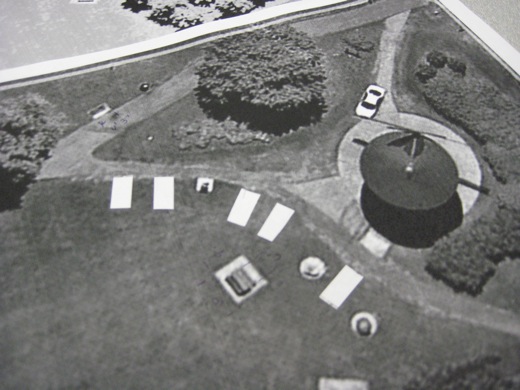

Darren did some measuring of the community garden site and made some scale-paper models of the planting beds.

This formation will likely be the way that we set up the garden.

Darren points out the lay of the land.

Here are some suggestions of potentially ways for arranging the plants in the beds.

I took notes.

The next day, the planters are drying in my studio.

They look good, though a couple might need more than one magnet.

Hard to believe we only ended up with ten planters, it was a lot of work, but this is a great start. Next step is to secure the magnets to these, get some soil and seeds, stencil the outsides and then get them up around the city.

i was thinking too, if you use a soil-less mix it’s very light, and you don’t need to fill the whole container with it. you can fill the bottom half with something airy and light to help drainage.

Good call! Any ideas of what this soil-less mix could be?

it’s at any place you buy plants. like cdn tire garden center. maybe inside though since it’s usually used for other plants indoors. like orchids or african violets i think. it’s very light.

http://gardening.about.com/od/seedsavin1/a/Potting_Mix.htm

just google soilless mix to learn more. we used it in the greenhouse a lot

did the triangular-ish planter end up working out?

i’m going to see if i can get some lego boxes built in the next couple days, and i’ll bring them out tuesday.

I stopped by the other day to check how they were drying. There’s some issues with actually removing the planters from whatever we molded them around… something to tackle on Tuesday…